Transporting a vertical air compressor is no easy task. They’re tall, heavy, and awkward to handle. That being said, you’ll want to make sure you have a plan in place prior to picking up your new air compressor to ensure you can load and unload it safely. The last thing you want is to damage your new investment before getting to use it, or worse yet, getting yourself hurt!

Table of Contents

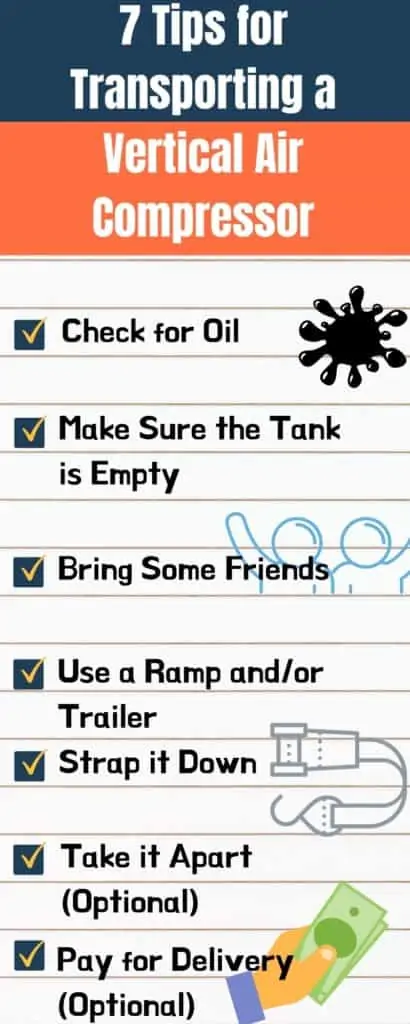

- 1. Check Whether It Has Oil In It

- 2. Make Sure the Storage Tank Is Empty

- 3. Bring Friends

- 4. Use a Ramp and/or Trailer

- 5. Secure Your Air Compressor Tightly

- 6. Take It Apart (Optional)

- 7. Pay for Delivery Service (Optional)

- Transporting A Vertical Air Compressor FAQ’s

So here are a few tips and tricks to help you move your vertical air compressor safely and (somewhat) easily.

1. Check Whether It Has Oil In It

Before you make a transportation plan, you’ll want to know whether the air compressor is an oil-lubricated or oil-free model. If it’s an oil-lubed compressor, you’ll want to avoid laying it on its side, as this can cause the oil in the pump to leak into places it’s not supposed to be, potentially damaging components – not to mention making a mess in your vehicle.

Fortunately, most new oil-lubed air compressors are sold without any oil in them. But some models are pre-filled, so make sure before you try to schlep it onto your vehicle. If you’re buying a used compressor, chances are it will have oil in it.

If it contains no oil, you should be fine laying it down on its side to transport it. Otherwise, you’ll want to drain the oil before attempting to lay it down. This will mitigate the risk of getting oil where it’s not supposed to be – but to be clear, there will still be a risk.

It’s also a good idea to wait 24 hours or more before firing it up if you decide to move it this way, to allow any residual oil to drain back down into the sump.

2. Make Sure the Storage Tank Is Empty

Putting an air compressor on its side can also be problematic if the storage tank contains any water. Condensation is a natural byproduct of compressing air, but when it collects inside the air storage tank, it can mix with any particulate matter that has escaped the air filter and made its way into the tank, forming a sludge. When the compressor is laid down, the sludge can get onto the inlet check valve and cause problems.

If you’re buying used, you’ll just want to make sure the tank has been completely drained. Fortunately, if you’re buying a new compressor, you shouldn’t have to worry about this. But when in doubt, it’s best to keep your air compressor upright.

3. Bring Friends

Another factor to consider is the weight of your air compressor – some larger models weigh anywhere from 250-600 pounds (or more). Unless your chosen air compressor is fairly compact and lightweight, you’ll want to bring plenty of muscle along to help you get the beast in and out of your vehicle.

4. Use a Ramp and/or Trailer

No matter how much help you have, you can make your life a lot easier by using a ramp. If you’re putting your air compressor in the bed of a pickup truck, this will make getting it on and off much easier – you can simply roll it up and down (carefully) using a hand truck or furniture dolly. If your compressor is especially heavy or is bolted to a pallet, however, a hand truck may not be feasible.

This may still be challenging due to the height of the pickup bed, so it may be better to rent or borrow a trailer. Not only will this be lower to the ground (which means a shorter ramp), but it will likely make it easier to tie your compressor down when the time comes (more on that shortly).

A trailer may also be the only choice if you have an SUV, a smaller vehicle, or a pickup with a covered bed and can’t fit the compressor without laying it down.

5. Secure Your Air Compressor Tightly

Whether you’ll be keeping your compressor upright or laying it down on its side to transport it, you’ll want to make sure it doesn’t move around on the drive. This is especially important if it’s upright – air compressors tend to be very top-heavy, so if it tilts at all, it will most likely go all the way. But even if it’s on its side, any movement can damage external components.

If you’re transporting a large vertical air compressor in the upright position, your best bet is to bolt it to a pallet for extra stability – fortunately, most new air compressors are sold this way already.

Once you’ve got your compressor in your trailer or truck, you’ll want to position it in the center of the bed and strap it down with heavy-duty ratchet straps. You’ll want to use at least four straps connecting it to each of the four corners of the truck bed or trailer – but it won’t hurt to use more. Just make sure they’re securely in place and ratchet them nice and tight!

6. Take It Apart (Optional)

If you need to lay down your compressor to move it but don’t want to risk any oil-related mishaps, you can remove the head and pump from the storage tank before transporting it. Of course, you’ll probably still want to drain the oil before moving it, but this way you can keep the pump upright.

But if you’re not confident you (or someone you know) can take apart an air compressor and put it back together again safely, you’re better off not going this route.

7. Pay for Delivery Service (Optional)

If all of the above sounds like too much of a hassle or you just don’t want to risk it, you may want to consider simply shelling out to have it delivered by professionals. In some cases, the fee may seem exorbitant, but it might be worth it, considering the labor involved in tackling it yourself and what you may have to spend on ratchet straps, trailer rental, etc. – not to mention the peace of mind that comes with hiring a pro.

Of course, not all sellers offer this service, so you’ll have to check beforehand. If all else fails, you can hire a local moving company to move it for you – provided that they know what they’re doing. In the end, you’ll just need to weigh your options to find out what works best for you.

Transporting A Vertical Air Compressor FAQ’s

How do I transport a vertical air compressor safely?

To transport a vertical air compressor safely, you should first make sure it is properly secured and immobilized to prevent it from tipping or sliding during transit.

This can be achieved by using tie-down straps or a support frame. Additionally, you should drain any remaining air and oil from the compressor tank and disconnect any attached hoses or cords.

Can I transport a vertical air compressor in an upright position?

Yes, a vertical air compressor is designed to be transported in an upright position. However, it is important to ensure that it is properly secured and supported to prevent damage to the compressor or surrounding equipment during transport.

What is the maximum angle at which a vertical air compressor can be transported?

The maximum angle at which a vertical air compressor can be transported varies depending on the model and manufacturer’s specifications. However, it is generally recommended to avoid tilting the compressor more than 15-20 degrees from its vertical position.

How should I prepare my vertical air compressor for transport if it has been recently used?

If your vertical air compressor has been recently used, you should allow it to cool down and release any remaining pressure in the tank before preparing it for transport. This will prevent the compressor from overheating during transport and reduce the risk of injury or damage.

Can I transport a vertical air compressor in a passenger car?

Transporting a vertical air compressor in a passenger car may be possible depending on the size and weight of the compressor and the available space in the car. However, it is generally recommended to transport the compressor in a vehicle with a flatbed or trailer to ensure safe and secure transportation.