If you’re thinking about buying a new air compressor, two key measurements that you need to be familiar with are PSI and CFM. Understanding what these measurements are, how they relate to one another, and how they affect the performance of your air tools will go a long way towards helping you find the right air compressor for your needs.

Although PSI and CFM are closely related, their difference lies in what they measure. PSI, or Pounds per Square Inch is used to measure force whereas CFM, or Cubic Feet per Minute, is used to measure volume. In simpler terms, PSI represents the pressure of the air that a given compressor can provide while CFM represents the amount of air that can be supplied. Both of these measurements, along with HP (horsepower), duty cycle, and tank size, help gauge an air compressors overall abilities and should be thoroughly considered prior to purchasing a new air compressor.

Throughout the rest of this article, we’ll take a closer look at PSI and CFM so you can determine which air compressor is right for you.

Table of Contents

What is PSI?

PSI (Pounds per Square Inch) represents the amount of pressure being applied to a single square inch of space. To help visualize what this looks like, imagine a 200 pound man standing on a single toe in an area roughly the size of a stamp. Because all of his bodyweight is centered in a one square inch area he is delivering 200 PSI. If he were to place his entire foot on the ground, however, he would no longer be delivering 200 PSI because his body weight wouldn’t be centered to a single square inch spot.

How Much PSI do I Need?

The only way to determine how much PSI you need is to first determine what kind of air tools you’ll be using and what their PSI requirements are. Most air tools operate in the range of 70-90 PSI but you should be able to find the specific PSI requirements for your tools in their owners manual.

That being said, most air compressors on the market today are capable of producing up to 150 PSI, which is more than enough to power all the air tools you’d typically be using at home. If, however, your tools require more than 150 PSI, you’ll have to find a more adequate air compressor that can produce the amount of pressure you need.

Respect Your Tool’s PSI Ratings

Another thing to mention is that all air tools have specific PSI ratings that they’re designed to operate at. If you don’t provide them with enough PSI then they may not function properly. If you give them too much you could damage them. Always use your air tools in accordance with their specific PSI requirements.

Remember, just because an air compressor is capable of producing 150 PSI doesn’t mean you have to supply that amount to your tools. Doing so won’t improve their performance. Be sure to regulate the amount of PSI being supplied to your air tools by adjusting your regulator as necessary. Also, be sure to check your gauges periodically just to make sure your operating in the safe zone.

If you’re not sure how to use an air compressor or how to regulate its PSI then be sure to check out my article on using an air compressor for the first time for a complete walkthrough.

What is CFM?

CFM (Cubic Feet per Minute) represents the amount of compressed air being supplied in one minutes time. It has nothing to do with the force or pressure of the air being supplied, but its quantity or volume. If your air compressor has a rating of 5.3 CFM, this means that is capable of producing 5.3 cubic feet of air per minute that its running.

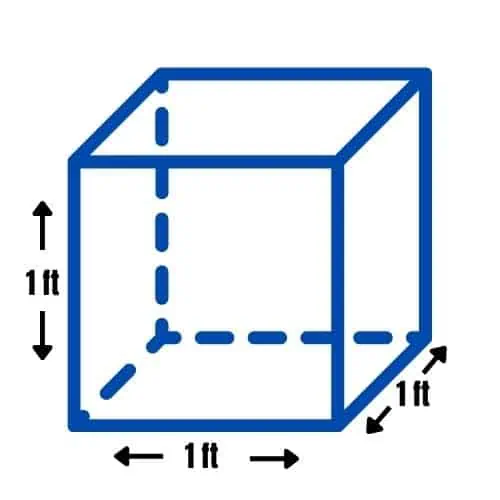

To help put that in perspective, one cubic foot is equivalent to about 7.5 gallons in terms of volume. A cubic foot can also be visualized as a cube that measures 12″x12″x12″.

Another way of understanding CFM is to view it as the compressors flow rate or output of air. Every air tool needs a specific amount of compressed air in order to operate. Whether or not a given compressor can meet that requirement will be determined by how much air its able to produce.

How Many CFM Do I Need?

Just like PSI, every air tool has a specific CFM rating at which it was designed to operate. If your compressor isn’t rated high enough to match your air tools requirements, then your air tools aren’t going to function properly. With that in mind, its crucial that you select an air compressor that produces enough CFM to run all your air tools efficiently.

To figure out how many CFM you need you’ll first need to see how many CFM your air tools require and then multiply that number by 1.5. For example, lets say the most demanding air tool you plan on using is an air grinder that needs 4 CFM to operate, you’ll want to buy an air compressor with a CFM rating of at least 6.

*4 x 1.5 = 6 CFM

If you plan on running multiple air tools at the same time, you’ll want to add their respective CFM requirements together and multiply that number by 1.5. If, for example, you plan on running an air grinder that needs 4 CFM to operate and a 1/4 air ratchet that needs 4.2 CFM, you’ll need an air compressor capable of producing 12.3 CFM.

*4 + 4.2 x 1.5 = 12.3 CFM

Pay Attention to CFM

When it comes to selecting an air compressor, the CFM rating is a bit more critical than the PSI rating. Because most compressors for home use are rated for 150 – 175 PSI, they’re more than capable of producing enough pressure for most air tools to operate properly. CFM ratings, on the other hand, can vary drastically. That being said, don’t just assume that the compressor you’re thinking about buying will work simply because it produces 150 PSI. If it’s CFM rating isn’t high enough to meet the requirements of your air tools, its simply not going to work for you.

What Size Air Compressor Do I Need?

So, what size air compressor do you need? If you’ve made it this far in the article you probably realize that there’s no blanket answer to this question. What size compressor you need will depend largely upon the tools that you’ll be using and their respective PSI and CFM requirements. That being said, I’ve decided to put together an Air Tool CFM Chart of some common air tools to help give you an idea of what size air compressor you’ll need.

Air Tool CFM Chart

| Tool | Working Pressure | CFM Requirement | Min. Compressor Rating |

|---|---|---|---|

| Brad Nailer | 60-90 PSI | 1 | 1.5 CFM |

| Framing Nailer | 90 PSI | 2.5 | 3.7 CFM |

| Roofing Nailer | 70-120 PSI | 2.5 | 3.7 CFM |

| 1/4 Ratchet | 90 PSI | 4.2 | 6.3 CFM |

| 3/8 Ratchet | 90 PSI | 4.4 | 6.6 CFM |

| 3/8 Air Drill | 90 PSI | 6.8 | 10.2 CFM |

| 1/2 Impact Wrench | 90 PSI | 5 | 7.5 CFM |

| 1/4 Angle Die Grinder | 90 PSI | 4.5 | 6.7 CFM |

| Air Hammer | 90 PSI | 4.4 | 6.6 CFM |

| 6″ Palm Sander | 90 PSI | 4.5 | 6.7 CFM |

| HVLP Paint Spray Gun | 30 PSI | 8 CFM | 12 CFM |

| 3″ Cut Off Tool | 90 PSI | 4.5 CFM | 6.7 |

This table is far from exhaustive but it gives a pretty good idea of the CFM requirements of different air tools and what size air compressor is needed to power them.

If you’d like to learn more about the different operational metrics used to gauge an air compressors overall abilities, check out the following articles:

- Air Compressor Duty Cycles Explained

- Air Compressor Measurements Explained (PSI, CFM, HP, & more)

- What is CFM on an Air Compressor?

Or, if you want to know what size air compressor you need for your home garage, check out this article:

CFM vs PSI FAQ’s

How do CFM and PSI work together?

CFM and PSI are related in that a higher CFM generally requires a higher PSI to maintain the necessary pressure to deliver the air flow. However, the relationship between CFM and PSI is not linear or always proportional.

Why is CFM important?

CFM is important because it determines the amount of air a compressor can deliver at a certain pressure level, which is crucial for many compressed air applications. Having a high CFM means that the compressor can deliver enough air to power larger pneumatic tools or equipment, whereas a small compressor with a low CFM may not be able to deliver enough air to operate those same tools.

Why is PSI important?

PSI is important because it determines the amount of pressure the compressor can deliver, which is necessary for many compressed air applications. A higher PSI means that the compressor can deliver more pressure, which is important for tasks like inflating car tires or running tools that require a certain pressure level to operate effectively.

How are CFM and PSI typically written for a compressor?

CFM and PSI are typically listed together for a compressor, such as “5 CFM at 90 PSI”. This means that the compressor can deliver 5 cubic feet of air per minute at a pressure of 90 pounds per square inch.

How can I find the right CFM and PSI for my needs?

The right CFM and PSI for your needs depend on the specific compressed air applications you have. You can consult with air compressor experts or look at the requirements for the pneumatic tools or equipment you want to use to determine the necessary CFM and PSI. It’s also important to consider factors like the compressor’s motor, service life, and weight to ensure it will work effectively for your needs.